Laminar air flow is air flow that constantly moves at the same speed in the same direction. In cleanrooms, a vertical laminar flow room is an enclosure where 100% of the ceiling provides filtered air downwards from the ceiling. Because of the 100% filter coverage, it creates an ultra-clean environment. But it’s much easier to achieve laminar flow in a smaller space, as equipment, personnel, and movement in a room cause turbulence that disturbs airflow.

A laminar flow hood is a device or enclosure commonly used as an ultra-clean workbench in laboratory applications. Filtered air sweeps particles in a uniform speed and direction from the hood’s most treated area (the filter) to its exit area.

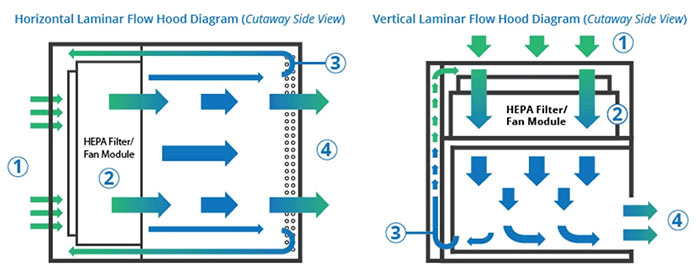

Cleanroom airflow uniformity and laminar flow hoods are essential to ensuring that sensitive products placed under the hood are always upstream and therefore suffer little to no contamination. Flow hoods come in two configurations: horizontal and vertical. Both designs provide an effective sweeping action through the work zone and meet ISO Class 5 cleanliness standards, so your application will help determine which is better for your facility.

This article will discuss the differences between horizontal vs. vertical laminar flow hoods and help you determine which is best for your application.

HORIZONTAL LAMINAR FLOW HOODS

Horizontal laminar flow hoods direct air, well, horizontally. Air is pushed through a HEPA or ULPA filter positioned on the back wall and moves forward across the work surface until it exits the enclosure.

By sweeping the air across the work surface and towards the operator, horizontal laminar flow hoods provide the highest protection from contaminating particles. No turbulence is caused by vertical air striking a perpendicular surface or the hands of the operator since they’re always further downstream than the materials they are working on.

However, the hood’s size, the filter’s positioning, and the airflow’s direction can also result in some negative consequences. Below, we’ll detail the complete list of pros and cons for these types of hoods:

Pros

Low turbulence on the work surface due to air flowing parallel to the work surface

Easy to position products and materials close to the filter on the work surface

Little contamination from hands or gloves due to the operator being downstream from products and materials

Cons

Requires hood repositioning to gain rear access for filter changes and servicing

Objects can obstruct the flow and contaminate anything downstream

Operators could suffer from fume or powder contaminants blowing at them if they don’t use the sash correctly

VERTICAL LAMINAR FLOW HOODS

In contrast, vertical laminar flow hoods take air from above the unit, push it through the HEPA or ULPA filter, then direct it down onto the work surface, where it eventually disperses and exits the enclosure out of a front access area. They resemble the model of a laminar flow cleanroom with fan filter units on the ceiling, just on a much smaller scale.

Vertical laminar flow hoods are popular because of their size, layout, and operator safety. Since the filter is at the top of the unit rather than behind, these flow hoods require less floor space but can be taller to fit larger products and materials. Also, since the laminar air isn’t blowing toward the operator, they are less likely to suffer any contaminants.

Vertical laminar flow hoods are an excellent choice for many applications, including handling sterile, non-hazardous drug compounding in research labs, pharmacies, and microbiology. Here’s a quick overview of their pros and cons:

Pros

Requires less floor space

Increased operator safety

Easy access to filter changes and servicing

Less cross-contamination of items on the work surface due to no parallel airflow

A taller system that can accommodate tall and large products and materials

Cons

It may require overhead clearance for changing and servicing the filter

Increased work surface turbulence due to vertical air hitting a perpendicular surface

Products and materials could obstruct airflow when stacked

WHICH HOOD IS RIGHT FOR YOUR APPLICATION?

You can use both horizontal and vertical laminar flow hoods for many applications involving sensitive products and materials, including (but not limited to):

Injectable drugs

IV solutions

Tissue culture

Optics

Microelectronics

While both flow hoods are great for reducing contamination in a workspace, a few applications lend themselves more toward one or the other. Usually, the most important factors to consider when deciding include process location, clearance requirements, size of materials, work surface design, and operator safety.

That said, horizontal laminar flow hoods generally work best for applications that require minimal turbulence on the work surface and the highest level of object contamination control.

CONTACT THE EXPERTS

If your application’s process is performed above the work surface, a vertical airflow configuration may be ideal; particles inside a vertical unit settle at the bottom of the work surface before exiting the enclosure. These are also a popular choice for any applications involving materials that could be especially large or dangerous to the operator.

If your cleanroom requires laminar flow hoods, Angstrom Technology can design a cleanroom that will seamlessly meet your classification and industry requirements. Contact us to talk to one of our design engineers today.