Product Description

Ocean one piece cleanroom corner system is divided into three types, which are integrated one piece cleanroom circular corner system, one piece cleanroom L-shaped corner system,one piece cleanroom T-shaped corner system, factory prefabrication, direct stitching on site, reducing the use of aluminum profiles, Make the clean room more beautiful, more conducive to cleaning and process sterilization.

Advantage:

1.The one piece cleanroom corner systems completely eliminates various corner joints between cleanroom wall panels,factory prefabrication, on-site splicing, andmodule installation is convenient and quick.

2.Nearly the ultimate guarantee of smooth and smooth siding, avoiding joint cracking, dust and leakage affect the clean environment, more conducive to cleaning and process sterilization.

3. According to different environments, fireproof, heat preservation, noise reduction, moisture proof, etc., choose different core materials, adapt to different cleanroom requirements.

4. The cleanroom panel coating and material are selected according to the use environment. The modular cleanroom wall panel can directly open the hole and reserve the line pipe to improve the installation efficiency.

5. Widely used in cleanrooms such as pharmaceuticals, electronics, and food.

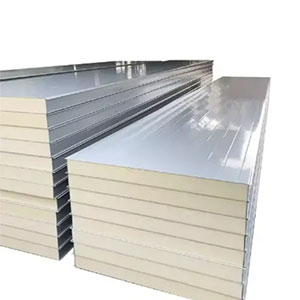

Product Parameters

| Width | 1180mm (width on both sides and not exceeding 1180mm) equal sides 315*315mm are recommended |

| Max Length | 6000mm |

| Wall TCK | 50mm/100mm |

| Steel TCK | 0.4mm-0.6mm |

| Outer Plate Material | PPGI,Al-mg-Mn Alloy steel,SS steel,Ti-Zn steel,VCM |

| HygiSteel™ - Customized color painted steel sheet for a better cleanroom environment | |

| Coating | PE,HDP,PVDF |

| Core Material | Rock Wool |

| Frame TCK | 0.6mm |

| Application | Pharmaceutical Clean Room,Electronic Clean Room,Food Clean Room,etc. |

| Remarks | The shape of this board is tracked by the cleaning technology department, and the size is issued by the technical department. |