Principle and characteristics

The INNOVE-HVAC series VHP sterilizer utilizes flash vaporization technology to vaporize 30%-35% hydrogen peroxide, which is then rapidly and evenly distributed throughout the sterilization space via the HVAC system, achieving comprehensive sterilization with zero blind spots. After sterilization, hydrogen peroxide undergoes rapid degradation, leaving no toxicity or residue. The system employs a modular design with four parallel VHP generation modules to ensure reliability. The sterilization process is controlled based on saturation and dew point to maintain the gaseous state of hydrogen peroxide. The equipment is made of stainless steel, featuring a smooth and seamless surface. The user-friendly interface allows for easy operation and quick mastery of the techniques. With a project management and execution team, the system offers turnkey solutions in the pharmaceutical, biosafety, medical, and public safety fields, covering design, production, installation, commissioning, parameter development, and validation services.

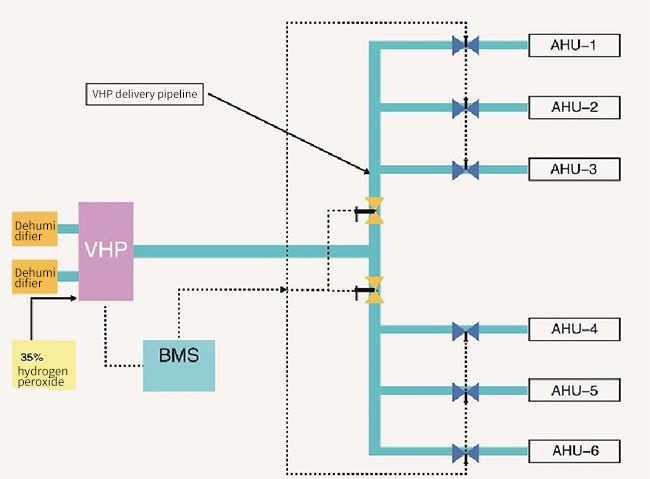

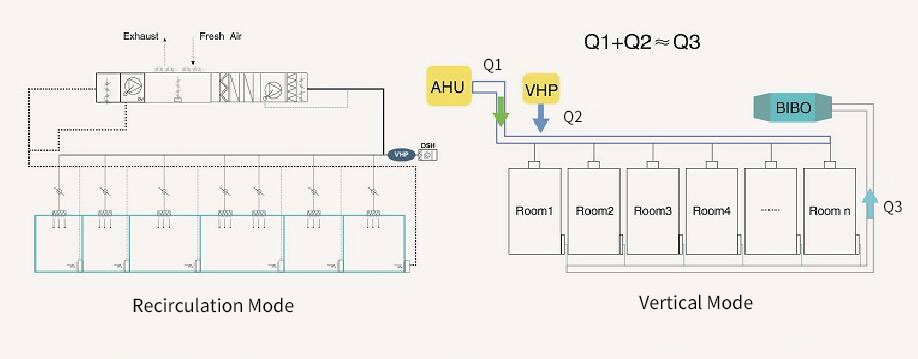

HVAC connection

Installation/connection method

Precautions or Important Considerations

Control of hydrogen peroxide vaporization during the entire sterilization process.

Generation of hydrogen peroxide: Ensure complete disruption of hydrogen bonds using flash evaporation.

Transportation of hydrogen peroxide: New air temperature and humidity, airflow, pipeline preheating, pipeline airtightness.

Process control: Saturation, dew point control, and cold point control.

Coordination with the HVAC system.

Cyclic or non-cyclic mode.

Disinfection mode: Dehumidification, closing of chilled water, restoring room temperature, frequency reduction (around 10 times).

Sealing of air ducts: Material of air duct sealing ring (chloroprene rubber).

Requirements for VHP transportation pipelines.

Attention to regional and seasonal variations.

Insulation, sealing, and corrosion resistance of

Parameters

| Size | 1800x2000x900mm |

| Vaporization rate | 20-160ml/min |

| Power | 15kw |

| Airflow | 100-1000cm³/h |

| Sterilization time | 60-360min |

| Weight | 150kg |