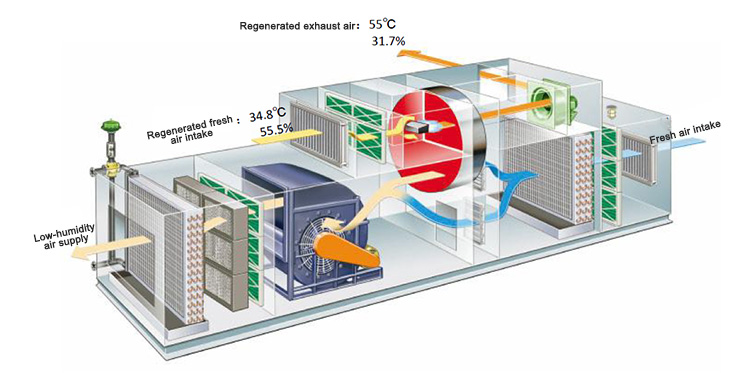

The low dew point rotary dehumidifier utilizes an advanced silica gel and molecular sieve honeycomb adsorption drying wheel, which boasts exceptional adsorption capabilities. As humid air passes through the wheel, moisture is effectively absorbed, and the filtered air is thoroughly processed into ultra-low dew point air, achieving a dew point temperature of -60°C or below. This fully meets the specialized environmental requirements for lithium battery production and pharmaceutical manufacturing.

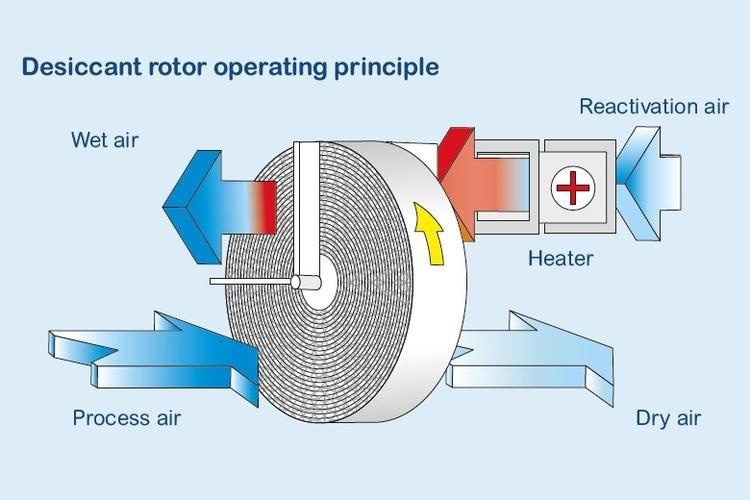

The principle of low dew point rotary dehumidification involves transferring the heat of the regenerated air, which has undergone secondary wheel treatment, to the primary regeneration zone, thereby reducing the moisture content of the unheated regenerated air. When the wheel rotates to the pre-treatment zone, it cools this area, enhancing the efficiency of low-temperature dehumidification. The heat is then absorbed by the regenerated air before heating, simultaneously increasing the temperature of the regenerated air. This process effectively reduces the energy consumption of the regeneration heater. Additionally, the temperature of the dehumidified air is lower, and the low dew point treatment can reduce the moisture content in the air to 0.5~1g, making it more difficult for water vapor in the air to condense. This achieves the dual goals of lowering regeneration energy consumption and reducing the air's dew point value.