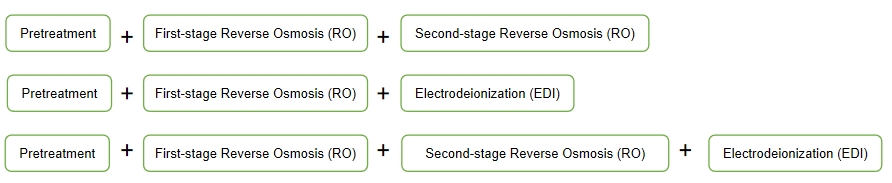

The biopharmaceutical purified water preparation system follows a modular design concept, based on functional units such as pretreatment, RO (Reverse Osmosis) reverse osmosis, UV disinfection, EDI (Electrodeionization) continuous deionization, and storage and distribution. It caters to the water needs of various pharmaceutical industries, including chemical APIs (Active Pharmaceutical Ingredients), chemical preparations, traditional Chinese medicine decoctions, proprietary Chinese medicines, and biopharmaceuticals. Depending on the specific water quality standards required by each industry, the final water production unit is optimized and assembled through a combination of various functional modules. This ensures high performance and high quality of the entire system, enabling the produced water to fully meet or exceed the water quality standards for purified water.

Process Flow

Reference Regulations and Standards

Compliant with the requirements of the Chinese Pharmacopoeia, European Pharmacopoeia, United States Pharmacopeia, standards for laboratory testing of ultrapure water, Good Manufacturing Practices (GMP), Food and Drug Administration (FDA), and other relevant standards.

Disinfection Methods (Optional): Activated Carbon Pasteurization, CIP Cleaning System, Ozone Sterilization of Distribution System, Pasteurization of Distribution System, Pure Steam Sterilization of Distribution System.

Provide the required DQ (Design Qualification), FAT (Factory Acceptance Test), SAT (Site Acceptance Test), IQ (Installation Qualification), OQ (Operational Qualification), and PQ (Performance Qualification) validation documents for the equipment;