Discover our solutions for Semiconductor

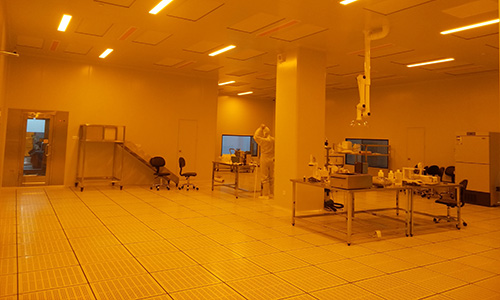

As the critical linewidth dimensions of electronic semiconductor chips shrink, evolving from the early micrometer (μm) level to the current nanometer (nm) level, the cleanliness requirements for chip manufacturing have become increasingly stringent. If the air cleanliness during the production process fails to meet the required standards, the product yield will be significantly affected. Almost all major segments of the integrated circuit industry chain, from monocrystalline silicon wafer manufacturing to IC manufacturing and packaging, need to be completed in clean rooms with very high cleanliness requirements. As a significant supplier to large-scale chip and liquid crystal display panel manufacturers in China, Aosheng provides these industries with air purification products and decorative structural materials that meet cleanliness standards, offer high efficiency, low energy consumption, and low noise.Furthermore, with the continuous improvement and iteration of manufacturing processes, merely controlling particulate matter is no longer sufficient to enhance yield. The control technology for airborne molecular contamination (AMC) has become a necessary means for improving semiconductor yield.

Enhance cleanliness and stability

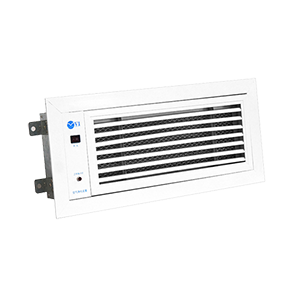

High-quality anti-static and anti-corrosion purification products significantly enhance and stabilize the cleanliness level of the cleanroom.

Guarantee product quality and safety

Ultra-clean solutions not only effectively control particulate matter but also control AMC gaseous contaminants.

Reduce energy consumption and costs

Energy-efficient air purification equipment and HVAC systems, coupled with easily cleanable and maintainable renovation materials.

Our Services

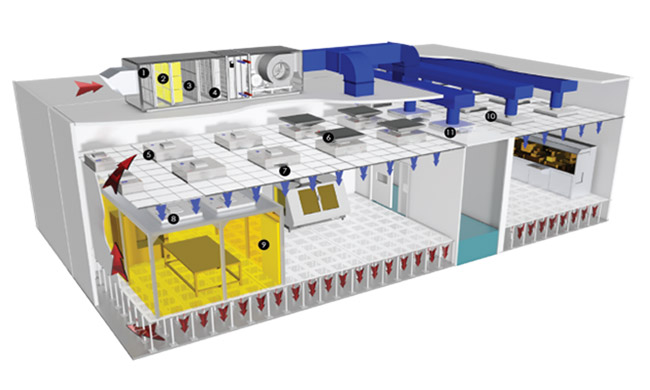

Planning and Design services for electronic cleanroom

● To understand the requirements and objectives of your microelectronics cleanroom project, and conduct assessments and research on the project budget allocation, project duration, spatial planning, among other aspects. This ensures that the project complies with relevant standards and regulations, achieving the expected outcomes in accordance with ISO 14644-1 to ISO 14644-5.

● For your microelectronics cleanroom project, we will provide detailed design drawings, encompassing structural components, HVAC systems, control systems, electrical parts, clean utilities, process equipment, and more.

Standardized or customized products for electronics cleanroom

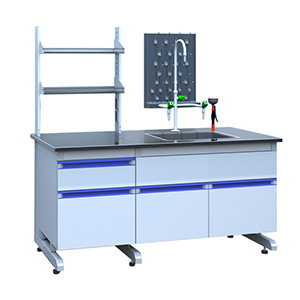

● We supply anti-static wall panels, ceilings, floors, lighting, and other architectural components for electronic cleanrooms. Additionally, we provide purification equipment such as high-efficiency filters, pass-through boxes, air showers, FFUs/EFUs, high-efficiency air outlets, clean benches, as well as chemical filters for AMC control. Furthermore, we offer a complete range of products including pure water equipment, HVAC systems, and cleanroom furniture.

● In addition to our portfolio, we are experienced with customizing, reconfiguring, and designing components to serve your needs, no matter how unique or unusual.

compliance consulting services for electronics cleanroom

● Our team possesses extensive knowledge and practical experience in biopharmaceutical cleanrooms, and is well-versed in GMP regulations and ISO standards. We provide compliant advice to optimize project design, layout, and manufacturing processes, ensuring that your project meets the necessary regulatory standards while fulfilling your process requirements. Our GMP consulting services are designed to support cleanroom users in navigating the complex requirements of Good Manufacturing Practices .