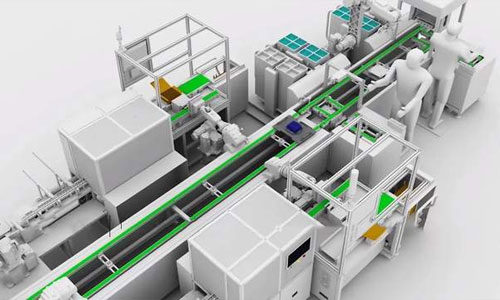

Discover our solutions for battery manufacturing

The production of lithium-ion batteries demands an extremely high level of environmental cleanliness, with each process step from slurry mixing to battery pack assembly having specific requirements for air quality. This is primarily to prevent impurities such as dust and metal particles from contaminating the battery materials, which could compromise the battery's performance and safety. The biggest difference between the lithium battery cleanroom and other industries is that the lithium battery cleanroom has higher requirements for humidity control, and the dehumidification unit is the core equipment to ensure the environmental dew point.Aosheng New Energy provides comprehensive solutions for cleanrooms involved in lithium-ion battery production (including workshops for lithium-ion batteries, dry/wet film production, cathode and anode materials, and lithium battery components), as well as for photovoltaic, wind energy, and hydrogen energy applications. These solutions encompass ultra-clean air purification systems, including air filters, FFU, high-efficiency air outlets, pass-through boxes, and air showers; interior decoration materials such as easy-to-clean, abrasion-resistant, and corrosion-proof purified color steel plates, floors, and suspended ceilings; lighting systems; and temperature and humidity control systems.

Protect process

Improve quality

Energy-saving

Strict standards

Applications

Walls and ceiling

The wall surfaces and ceilings usually adopt color steel plate materials. Their surfaces are flat and smooth, easy to clean, and have good air tightness. The joints between color steel plates are sealed with sealant to prevent air leakage and dust from entering.

lighting system

Cleanroom lighting generally uses clean fluorescent lamps or LED lamps. These lamps should have good sealing performance to prevent dust and moisture from entering. The lighting intensity should meet the requirements of production operations. Generally, it is between 300 and 500 lux. At the same time, shadows and glare should be avoided to ensure that operators can clearly see production details.

Floor and Windows

Floor material

The floor of a clean room generally adopts epoxy self-leveling ground or PVC anti-static ground. Epoxy self-leveling ground has the advantages of being seamless, flat, and corrosion-resistant, and can effectively prevent the generation and accumulation of dust. PVC anti-static ground can avoid damage to electronic equipment and battery materials caused by static electricity. Its surface resistance is generally between 10⁶ and 10⁹ ohms.

Window material

The door and window materials should be specialized for dust-free rooms, ensuring tight sealing and cleanliness.

Air Purification System

During the production process of lithium batteries, a significant amount of dust and harmful gases are generated. Besides requiring HEPA/ULPA air filters, FFUs (Fan Filter Units), and high-efficiency air supply outlets for purifying particulate matter, chemical filters are also necessary to remove harmful gases and prevent corrosion and damage to electronic components. Additionally, to avoid contamination from the movement of personnel and cargo, equipment such as transfer windows and air showers are required.

Temperature and Humidity Control System

The temperature and humidity control system for lithium battery clean rooms needs to meet the following key requirements and characteristics:

Strict temperature and humidity control: The temperature needs to be maintained between 20°C and 25°C,Lithium battery production (e.g., electrode coating, cell assembly) demands extremely dry conditions (often ≤1% RH), with specific processes even requiring a dew point temperature of ≤-60°C, to ensure battery performance and safety.

Moisture Control System: Rotary dehumidifiers efficiently remove moisture from the air, preventing electrolyte degradation and ensuring consistent battery performance.

High accuracy and stability: Advanced sensors and control systems are employed to achieve temperature fluctuations within ±0.5°C and humidity fluctuations within ±3%RH, ensuring long-term stable operation.

Intelligent management: Integrated with Internet of Things (IoT) technology, it enables remote monitoring, intelligent regulation, and data visualization, improving management efficiency and ensuring production safety.

Energy-saving and environmentally friendly: Optimized control algorithms and energy-saving equipment are adopted to reduce energy consumption and comply with environmental protection requirements.

Our Services

Planning and Design services for battery manufacturing cleanroom

● To understand the requirements and objectives of your battery manufacturing cleanroom project, and conduct assessments and research on the project budget allocation, project duration, spatial planning, among other aspects. This ensures that the project complies with relevant standards and regulations, achieving the expected outcomes in accordance with ISO 14644-1 to ISO 14644-5.

● For your battery manufacturing cleanroom project, we will provide detailed design drawings, encompassing structural components, HVAC systems, control systems, electrical parts, clean utilities, process equipment, and more.

Standardized or customized products for battery manufacturing cleanroom

● We supply anti-static wall panels, ceilings, floors, lighting, and other architectural components forbattery manufacturing cleanrooms. Additionally, we provide purification equipment such as high-efficiency filters, pass-through boxes, air showers, FFUs/EFUs, high-efficiency air outlets, clean benches, as well as chemical filters for AMC control. Furthermore, we offer a complete range of products including pure water equipment, HVAC systems, and cleanroom furniture.

● In addition to our portfolio, we are experienced with customizing, reconfiguring, and designing components to serve your needs, no matter how unique or unusual.

Compliance consulting services for battery manufacturing cleanroom

● Our team possesses extensive knowledge and practical experience in biopharmaceutical cleanrooms, and is well-versed in GMP regulations and ISO standards. We provide compliant advice to optimize project design, layout, and manufacturing processes, ensuring that your project meets the necessary regulatory standards while fulfilling your process requirements. Our GMP consulting services are designed to support cleanroom users in navigating the complex requirements of Good Manufacturing Practices .