Discover our solutions for Food, Beverage, and Cosmetics cleanroom

Hygiene & safety

Extended Shelf Life

Cost Savings

Increased Sales

Applications

Walls and ceiling

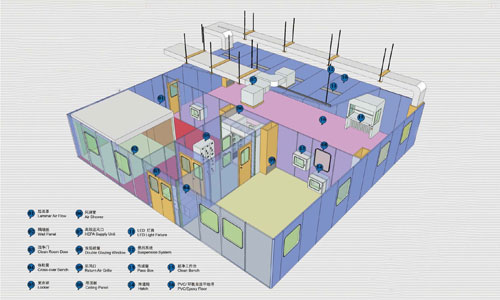

According to the "Design Specifications," the walls and ceiling of the workshop must be constructed using materials that do not generate or accumulate dust, and have a smooth surface. Specialized color-coated steel plates for clean room construction are used, with stainless steel plates for the wall panels and ceiling panels, with a density of 14kg/m³. Specialized aluminum profiles are employed, and to enhance the service life of the purification room and achieve an aesthetically pleasing appearance, all aluminum profiles undergo electrophoretic treatment.

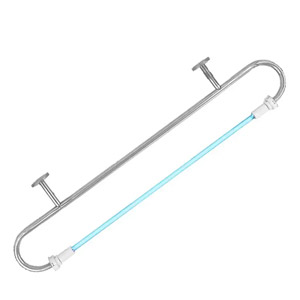

Lighting: Ceiling-mounted purification lamps should be used in clean areas, while ordinary fluorescent lamps should be used in non-clean areas.

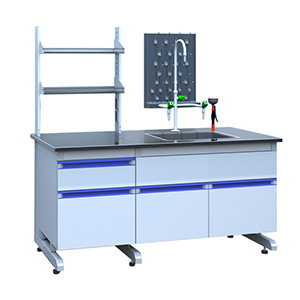

Floor and Windows

Floor material

According to the "Design Specifications," the walls and ceilings of the workshop must be constructed using materials that do not generate or accumulate dust, featuring smooth surfaces. Cleanroom-specific color steel plates or stainless steel plates should be employed; dedicated aluminum profiles should also be used. To enhance the service life of the purified room and achieve an aesthetically pleasing appearance, all aluminum profiles undergo electrophoretic treatment. Avoid dead corners and grooves to minimize dust accumulation and microbial growth.

Window material

The door and window materials should be specialized for dust-free rooms, ensuring tight sealing and cleanliness.

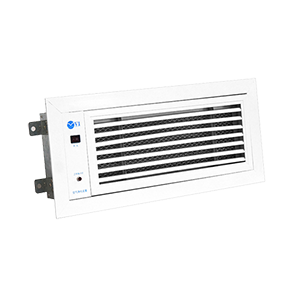

Air Purification Solution

The air purification solution for food clean rooms is a crucial aspect in ensuring food safety and hygiene. A multi-stage filtration system can reliably filter out particulate matter and microorganisms in the air. Depending on the cleanliness requirements of different areas, air filtration equipment such as HEPA (High-Efficiency Particulate Air) and medium-to-high efficiency filters, FFU/EFU (Fan Filter Units/Enclosed Fan Units), as well as sterilization and disinfection equipment like UV light, ozone, hydrogen peroxide, air-conditioning sterilization systems, sterile transfer hatches, and air showers are employed.

Temperature and Humidity Control System

The temperature and humidity control system in food clean rooms needs to ensure high precision, stability, and energy efficiency to meet food safety and quality standards. The system employs advanced control algorithms and technologies to achieve interconnected multi-variable control of temperature and humidity, and possesses characteristics such as intelligent management, scalability, and ease of maintenance, in order to accommodate the processing and storage requirements of various food products.

Our Services

Planning and Design services for food, beverage, and cosmetics cleanroom

● To understand the requirements and objectives of your food, beverage, and cosmetics cleanroom project, we will conduct assessments and investigations into the project's budget allocation, project timeline, spatial planning, and other relevant aspects, ensuring that the project complies with GMP/ISO 14644 standards and other regulations, and achieving the anticipated results.

● For your food and beverage cleanroom project, we will provide detailed design drawings, encompassing structural components, HVAC systems, control systems, electrical parts, clean utilities, process equipment, etc.

Standardized or customized products for food, beverage, and cosmetics cleanroom

● We provide products of standard specifications for cold storage, including ceilings, wall panels, lighting, refrigeration equipment, etc.

● In addition to our portfolio, we are experienced with customizing, reconfiguring, and designing components to serve your needs, no matter how unique or unusual.

Compliance consulting services for food, beverage, and cosmetics cleanroom

Our team possesses extensive knowledge and practical experience in food and beverage cleanrooms, and is well-versed in GMP regulations and ISO standards. We provide compliant advice to optimize project design, layout, and manufacturing processes, ensuring that your project meets the necessary regulatory standards while fulfilling your process requirements. Our GMP consulting services are designed to support cleanroom users in navigating the complex requirements of Good Manufacturing Practices (GMP).